Pressure Former

Product Details:

Pressure Former Price And Quantity

- 01 Unit

Pressure Former Trade Information

- Nhava Sheva Port

- 01 Unit Per Month

- Yes

- Contact us for information regarding our sample policy

- Australia North America South America Eastern Europe Western Europe Middle East Central America Asia Africa

- All India

Product Description

Pressure Former

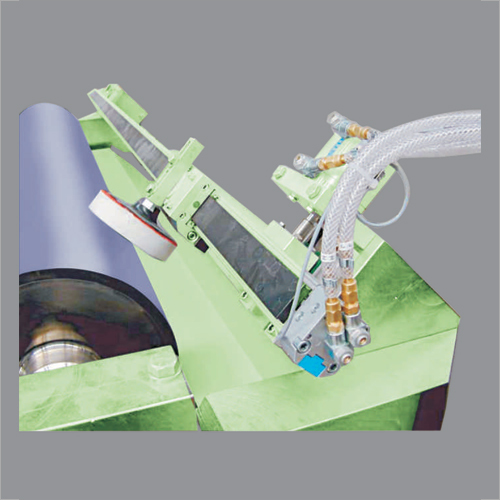

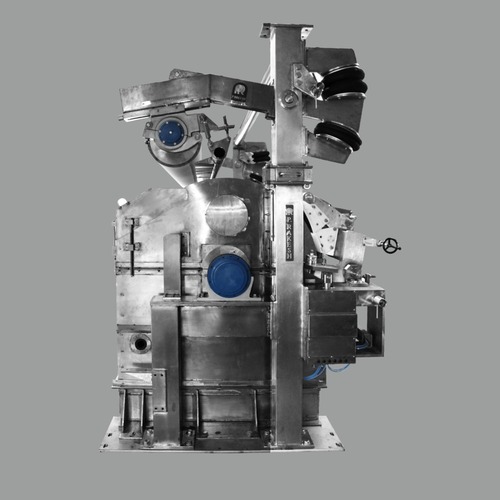

The cylinder mould pressure former is one of the most efficient technology for multilayer paper/board manufacturing. Each unit is a complete system and can be combined with identical units to make multilayer board forming unit. PRI former is capable of producing board with minimum cross profile variation even at higher speed.

The forming head is designed for wide range of operations for producing various types of boards. To cope with change in GSM range the gap between the cylinder mould and Stainless Steel forming lip can be adjusted by precise micrometer provided at both ends. PRI former is also equipped with throat adjuster mechanism which is operated by handwheel. The inlet centrifugal distributor is highly finished internally for smooth pulp entry into former explosion chamber. The centrifugal distributor is equipped with dilution nozzles which further minimizes cross profile variation on board.

PRI forming unit and cylinder mould is enclosed in a vat which avoids water splashing at higher speeds keeping the floor clean and dry for trouble free operations. The vat is also equipped with air extraction pipe on side wall for air evacuation from cylinder mould.

KEY FEATURES OF PRI FORMER :

- Improved sheet strength

- Excellent sheet formation at all speed and substance

- MD/CD sheet gain ratio control

- Easy to operate-rapid start up

- Unaffected by normal freeness changes

- Higher speed capabilities

- Approaches fourdrinier type formation

- Basis weight and speed changes easily and quickly accomplished

- Superior sheet quality and test versus standard cylinder mould techniques

- Easy to maintain

Contact Us

Contact Us Send Inquiry

Send Inquiry Send SMS

Send SMS